Artist’s rendering of a hypersonic aircraft. Photo credit: Hermeus

High-efficiency 3D-printed catalytic converters could help solve the overheating problem in hypersonic aircraft and offer a revolutionary solution to thermal management in countless industries.

The highly versatile catalysts, developed by researchers at RMIT University in Melbourne, Australia, are inexpensive to manufacture and easy to scale up.

The team’s lab demonstrations show that the 3D-printed catalysts could potentially be used to power hypersonic flight while cooling the system.

The research is published in the journal Royal Society of Chemistry. chemical communication.

Lead researcher Dr. Selvakannan Periasamy said her work tackles one of the biggest challenges in developing hypersonic aircraft: controlling the incredible heat generated when planes fly at more than five times the speed of sound.

“Our lab tests show that the 3D printed catalysts we are developing show promise to power the future of hypersonic flight,” said Periasamy.

“They are powerful and efficient, and offer an exciting potential solution for thermal management in aerospace – and beyond.

“As development continues, we hope that this new generation of ultra-efficient 3D-printed catalysts can be used to transform any industrial process where overheating is a pervasive challenge.”

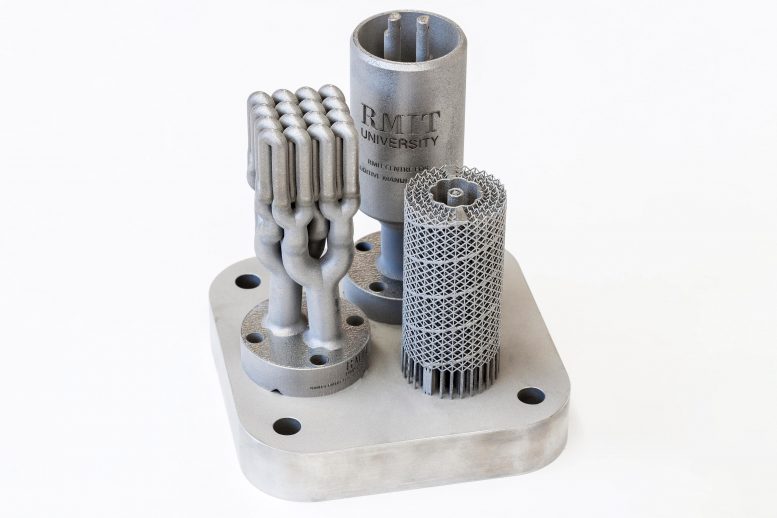

A set of experimental designs for the 3D printed catalysts. Photo credit: RMIT University

Need speed

Few experimental aircraft have reached hypersonic speed (defined as over Mach 5 – over 3,800 mph (6,100 km/h) or 1 mile (1.7 km) per second).

Theoretically, a hypersonic aircraft could travel from London to New York in less than 90 minutes, but many challenges remain in the development of hypersonic air travel, such as extreme heat.

First author and PhD student Roxanne Hubesch said using fuel as a coolant is one of the most promising experimental approaches to the overheating problem.

“Fuels that can absorb heat when powering an airplane is the focus of scientists, but this idea relies on heat-consuming chemical reactions that require highly efficient catalysts,” Hubesch said.

“In addition, the heat exchangers where the fuel comes into contact with the catalysts must be as small as possible due to the tight volume and weight constraints in hypersonic aircraft.”

To create the new catalysts, the team 3D printed tiny heat exchangers from metal alloys and coated them with synthetic minerals called zeolites.

Researchers replicated on a laboratory scale the extreme temperatures and pressures fuel is subjected to at supersonic speeds to test the functionality of their design.

Miniature chemical reactors

As the 3D-printed structures heat up, some of the metal migrates into the zeolite framework – a process that is key to the unprecedented efficiency of the new catalysts.

“Our 3D printed catalysts are like miniature chemical reactors, and what makes them incredibly effective is this mix of metal and synthetic minerals,” Hubesch said.

“It’s an exciting new direction for catalysis, but we need more research to fully understand this process and to identify the best combination of metal alloys for the greatest effect.”

The next steps for the research team from RMIT’s Center for Advanced Materials and Industrial Chemistry (CAMIC) include optimizing the 3D printed catalysts by studying them with X-ray synchrotron techniques and other in-depth analysis methods.

The researchers also hope to extend the work’s potential applications to air pollution control for vehicles and miniature devices to improve indoor air quality – particularly important in combating airborne respiratory viruses[{” attribute=””>COVID-19.

CAMIC Director, Distinguished Professor Suresh Bhargava, said the trillion-dollar chemical industry was largely based on old catalytic technology.

“This third generation of catalysis can be linked with 3D printing to create new complex designs that were previously not possible,” Bhargava said.

“Our new 3D printed catalysts represent a radical new approach that has real potential to revolutionize the future of catalysis around the world.”

The 3D printed catalysts were produced using Laser Powder Bed Fusion (L-PBF) technology in the Digital Manufacturing Facility, part of RMIT’s Advanced Manufacturing Precinct.

Reference: “Zeolites on 3D-Printed Open Metal Framework Structure: Metal migration into zeolite promoted catalytic cracking of endothermic fuels for flight vehicles” by Roxanne Hubesch, Maciej Mazur, Karl Föger, P. R. Selvakannan and Suresh K. Bhargavan, 25 August 2021, Chemical Communications.

DOI: 10.1039/D1CC04246G