Through David L. Chandler, Massachusetts Institute of Technology

March 18, 2022

Dust that accumulates on solar panels is a big problem, but washing the panels uses huge amounts of water. MIT engineers have now developed a waterless cleaning method to remove dust on solar arrays in water-limited regions, thereby improving overall efficiency. Credit: Courtesy of the researchers

A new cleaning method could remove dust on solar arrays in arid regions, improving overall efficiency.

Solar power is expected to reach 10 percent of global electricity generation by 2030, and much of that will likely be in desert areas where sunlight is plentiful. But dust accumulation on solar panels or mirrors is already a significant problem — it can reduce photovoltaic panel performance by up to 30 percent in just a month — so regular cleaning is essential for such installations.

But cleaning solar panels is currently estimated to use about 10 billion gallons of water a year — enough to provide drinking water for up to 2 million people. Attempts at waterless cleaning are labor intensive and tend to cause irreversible scratching of surfaces, which also reduces efficiency. Now has a research team[{” attribute=””>MIT has devised a way of automatically cleaning solar panels, or the mirrors of solar thermal plants, in a waterless, no-contact system that could significantly reduce the dust problem, they say.

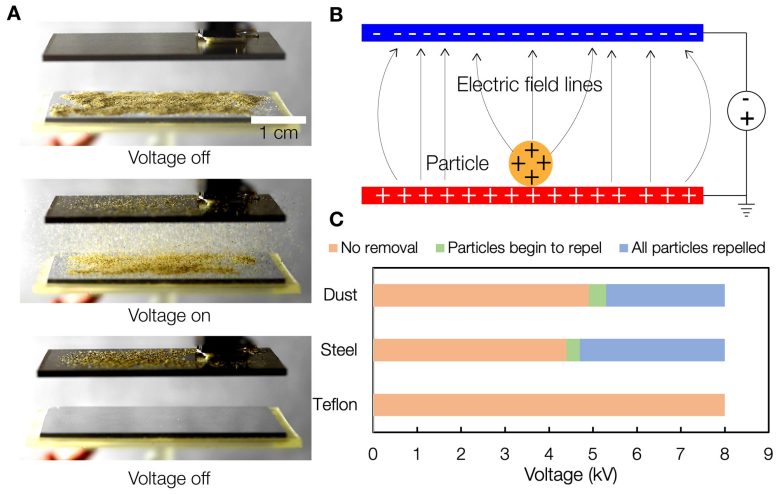

The new system uses electrostatic repulsion to cause dust particles to detach and virtually leap off the panel’s surface, without the need for water or brushes. To activate the system, a simple electrode passes just above the solar panel’s surface, imparting an electrical charge to the dust particles, which are then repelled by a charge applied to the panel itself. The system can be operated automatically using a simple electric motor and guide rails along the side of the panel. The research is described on March 11, 2022, in the journal Science Advances, in a paper by MIT graduate student Sreedath Panat and professor of mechanical engineering Kripa Varanasi.

Despite concerted efforts worldwide to develop more and more efficient solar panels, says Varanasi, “an everyday problem like dust can seriously affect the whole thing.” Laboratory tests conducted by Panat and Varanasi showed that the drop in energy output from the panels started at the very beginning of the process of dust accumulation occurs steeply and can easily achieve a 30 percent reduction after just one month without cleaning. Even a 1 percent reduction in output from a 150 megawatt solar array could result in a $200,000 loss in annual revenue. The researchers say that reducing solar power output by 3 to 4 percent worldwide would result in a loss of between $3.3 billion and $5.5 billion.

“There’s so much work being done on solar materials,” says Varanasi. “You’re pushing the envelope, trying to snag a few percent here and there in improving efficiency, and here you have something that can wipe out all of that in an instant.”

Many of the world’s largest solar power plants, including those in China, India, the United Arab Emirates and the US, are located in desert regions. The water used to clean these solar panels with pressurized water jets must be supplied remotely and must be very pure so as not to leave deposits on the surfaces. Dry scrubbing is sometimes used but is less effective at cleaning surfaces and can cause permanent scratches that also reduce light transmission.

Water purification accounts for about 10 percent of the operating costs of solar systems. The new system could potentially reduce those costs while improving overall performance by allowing for more frequent automated cleanings, the researchers say.

The new system uses electrostatic repulsion to cause dust particles to detach and pop off the surface of the disc with virtually no water or brushing required. Credit: Courtesy of the researchers

“The water footprint of the solar industry is amazing,” says Varanasi, and it’s set to increase as these installations continue to expand around the world. “So the industry has to be very careful and thought out how to make this a sustainable solution.”

Other groups have attempted to develop electrostatic-based solutions, but these have relied on a layer called an electrodynamic screen that uses interdigitated electrodes. These screens can have defects that allow moisture in and lead to failure, says Varanasi. While they might come in handy in a place like[{” attribute=””>Mars, he says, where moisture is not an issue, even in desert environments on Earth this can be a serious problem.

The new system they developed only requires an electrode, which can be a simple metal bar, to pass over the panel, producing an electric field that imparts a charge to the dust particles as it goes. An opposite charge applied to a transparent conductive layer just a few nanometers thick deposited on the glass covering of the the solar panel then repels the particles, and by calculating the right voltage to apply, the researchers were able to find a voltage range sufficient to overcome the pull of gravity and adhesion forces, and cause the dust to lift away.

Using specially prepared laboratory samples of dust with a range of particle sizes, experiments proved that the process works effectively on a laboratory-scale test installation, Panat says. The tests showed that humidity in the air provided a thin coating of water on the particles, which turned out to be crucial to making the effect work. “We performed experiments at varying humidities from 5 percent to 95 percent,” Panat says. “As long as the ambient humidity is greater than 30 percent, you can remove almost all of the particles from the surface, but as humidity decreases, it becomes harder.”

Varanasi says that “the good news is that when you get to 30 percent humidity, most deserts actually fall in this regime.” And even those that are typically drier than that tend to have higher humidity in the early morning hours, leading to dew formation, so the cleaning could be timed accordingly.

“Moreover, unlike some of the prior work on electrodynamic screens, which actually do not work at high or even moderate humidity, our system can work at humidity even as high as 95 percent, indefinitely,” Panat says.

In practice, at scale, each solar panel could be fitted with railings on each side, with an electrode spanning across the panel. A small electric motor, perhaps using a tiny portion of the output from the panel itself, would drive a belt system to move the electrode from one end of the panel to the other, causing all the dust to fall away. The whole process could be automated or controlled remotely. Alternatively, thin strips of conductive transparent material could be permanently arranged above the panel, eliminating the need for moving parts.

By eliminating the dependency on trucked-in water, by eliminating the buildup of dust that can contain corrosive compounds, and by lowering the overall operational costs, such systems have the potential to significantly improve the overall efficiency and reliability of solar installations, Varanasi says.

Reference: “Electrostatic dust removal using adsorbed moisture–assisted charge induction for sustainable operation of solar panels” by Sreedath Panat and Kripa K. Varanasi, 11 March 2022, Science Advances.

DOI: 10.1126/sciadv.abm0078

The research was supported by Italian energy firm Eni. S.p.A. through the MIT Energy Initiative.