Mark Skylar-Scott and his team of Stanford bioengineers aim to use advanced 3D printing techniques to turn a paste of living cells into hearts and other organs.

Few human organs are more alluring to an engineer than the human heart. Its chambers pump in perfect unison; its materials are pliable but contract when needed; Its shape and movement are perfectly tuned to efficiently push fluid throughout the body. It’s a structural marvel – but when something goes wrong within this structure, the inherent complexity makes it a real challenge to fix it. Thousands of young patients with congenital heart defects therefore have to cope with their disease for the rest of their lives.

“Pediatric heart disease is one of the most common forms of congenital birth defects in the United States,” said Mark Skylar-Scott, assistant professor of bioengineering in the engineering and medical schools. “It’s really hard for families. There are ways to extend children’s lives through surgery, but many children suffer from restricted mobility and live uncertain lives. To find a truly healing solution, you must somehow replace damaged or malformed tissue.”

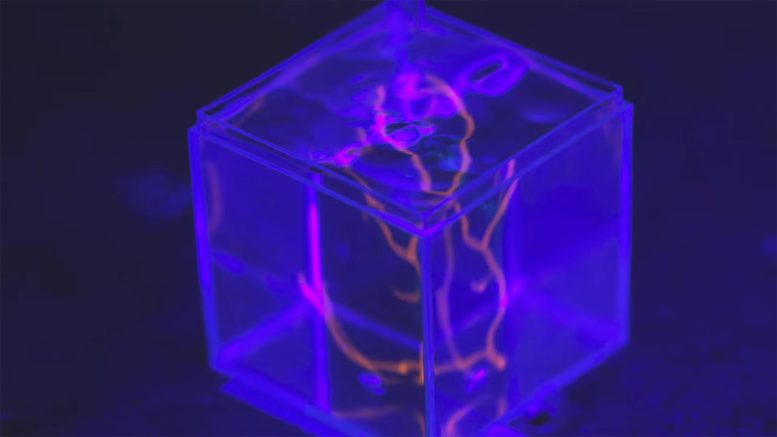

Stanford scientists are working to make human tissue on a therapeutic scale, with a focus on the heart. Photo credit: Kurt Hickman

That’s where Skylar-Scott comes in. He is working on new ways to tackle congenital heart defects by creating artificial heart tissue in the lab.

It takes far more than just culturing cells in a dish, he notes. Most existing techniques deploy heart cells or stem cells on a temporary “scaffold”: a porous, spongy substance that can hold them in place in three dimensions. Although this method allows researchers to grow lab-made tissue, it is only really practical for extremely thin layers of cells.

“If you have a scaffold that’s only a few cells thick, you can put the cells in the right place. But when you try to grow something that’s an inch thick, it becomes really difficult to seed cells in the right places to grow tissue. Keeping them alive, giving them the right nutrients, or vascularizing them becomes a real challenge,” says Skylar-Scott. Human organs are also not monolithic clumps of cells, he adds. Each is made up of complex layers of multiple cell types, resulting in a 3D structure that is incredibly difficult to replicate.

Print organoids

To circumvent this fact, Skylar-Scott and his team are working on a bold new approach to organ engineering. Using advanced 3D printing techniques, they craft thick tissues layer by layer, placing exactly the kind of cells needed in the right places, like a tower rising from a lattice of carefully placed bricks. This type of construction method, he notes, lends itself well to replicating complex tissues like the heart, where 3D shape is critical to its function.

As promising as it may be, cellular 3D printing comes with some profound and thorny challenges. Unlike plastic filaments, which consumer 3D printers can heat and press into myriad shapes, cells are alive. They’re soft, squishy, imperfect, and frustratingly fragile, says Skylar-Scott.

The 3D bioprinter prints a pattern. Credit: Andrew Brodhead

“If you try to place a single cell at a time, printing a liver or a heart can take hundreds or thousands of years. Even if you’re processing 1,000 cells per second, you still have to lay down many billions of cells to get an organ. If you do the math, it doesn’t look so good for a scalable process,” he says.

Instead, Skylar-Scott and his lab are working to speed up the printing process by depositing dense clumps of cells called “organoids.” The group makes these clumps by putting genetically engineered stem cells in a centrifuge, which creates a pasty substance. With this concoction, they can print large numbers of cells at once into a gelatinous 3D structure. “We basically define the large-scale structure of an organ by printing these organoids,” he says.

cell programming

However, attaching the stem cells is only the first step. Once printed, researchers must somehow convince them to differentiate into more specific cell types and form a multi-layered cluster of functioning groups of cells that resemble healthy organ tissue. To achieve this, Skylar-Scott essentially bathes the stem cells in a chemical cocktail.

“Each line of stem cells that we develop is genetically engineered to respond to a specific drug,” he notes. “Once they sense this drug, they differentiate into specific cell types.” Some cells are programmed to become cardiomyocytes, the heart cells that make up the functional core tissue in the heart. Others are instructed to become stromal cells that connect tissues together.

Skylar-Scott tests his printed tissues in a bioreactor, a smartphone-sized container that helps keep the printed cells alive. Inside, his team managed to grow a printed organ-like structure: a tube about 2 inches long and half a centimeter in diameter. Like a vein in the human body, this tiny device could “pump” itself, contracting and expanding to move fluid through itself.

“If we can engineer more tissues like this, we might have a good halfway to building something that can be implanted in the human body,” says Skylar-Scott. “In patients who were born with a single ventricle, for example, there is only one chamber in the heart that can push blood to the body and lungs – which puts a lot of strain on the cardiovascular system and leads to high blood pressure, which organs produce can harm. Something like this could act as a biological pumping device to move blood to and from the heart,” he says.

Enlarge

Skylar-Scott quickly realizes that the printing of a larger structure, such as a functional chamber, grafted onto an existing heart is a long way off. To accomplish that would mean growing a little more than 16 times the size of his lab’s experimental “vein pump.” To make anything even close to that size — or better yet, a whole new organ — his lab would have to increase cell production tremendously.

“Scale-up will be the challenge of our generation,” says Skylar-Scott. However, it will mean more just to build a bigger printer. In many ways, it comes down to the cells themselves.

“Right now it takes a month for enough cells to grow to print something tiny. It’s also extremely expensive – each test costs tens of thousands of dollars,” he says. “We need to find ways to engineer cells that are more robust and cheaper to grow so we can start practicing and perfecting this method.” Once the pipeline for new cells is in place, I think we’re going to see some incredible progress.”

2 Comments

Your comment is awaiting moderation.

It’s difficult to find well-informed people in this particular subject, however, you sound like

you know what you’re talking about! Thanks

Your comment is awaiting moderation.

A elaboração de sites em Sorocaba é uma necessidade para qualquer profissional que pretende marcar presença online.

Inúmeros empreendedores apostam cada vez mais em

projetos personalizados.

Outro ponto fundamental otimizar o conteúdo para atrair visitas qualificadas.

Your comment is awaiting moderation.

Incredible! This blog looks just like my old one! It’s on a totally

different subject but it has pretty much the same page layout and design. Wonderful choice of colors!

Your comment is awaiting moderation.

Thanks for sharing your info. I really appreciate your efforts and

I am waiting for your next post thanks once again.

Your comment is awaiting moderation.

Its not my first time to visit this website, i am

visiting this website dailly and obtain nice information from here every day.

Your comment is awaiting moderation.

Good day! I know this is kind of off topic but I

was wondering if you knew where I could locate a

captcha plugin for my comment form? I’m using the same blog platform

as yours and I’m having problems finding one? Thanks a lot!

Your comment is awaiting moderation.

Thanks for the marvelous posting! I genuinely enjoyed reading it, you are a great author.

I will make certain to bookmark your blog and definitely will come back someday.

I want to encourage yourself to continue your great work,

have a nice weekend!

Your comment is awaiting moderation.

Hi there mates, fastidious paragraph and nice urging

commented here, I am truly enjoying by these.

Your comment is awaiting moderation.

It’s actually a cool and useful piece of information. I’m glad that you simply shared this helpful information with us.

Please stay us up to date like this. Thanks for sharing.

Your comment is awaiting moderation.

Great post. I used to be checking constantly this weblog and I’m inspired!

Very useful information particularly the remaining section 🙂 I maintain such information a lot.

I was looking for this particular information for a very long time.

Thank you and good luck.

Your comment is awaiting moderation.

There’s certainly a lot to find out about this topic.

I love all the points you’ve made.

Your comment is awaiting moderation.

Hello! This is my first visit to your blog! We are a team of volunteers and starting a new project in a

community in the same niche. Your blog provided us useful information to work on. You have done

a wonderful job!

Your comment is awaiting moderation.

I was curious if you ever thought of changing

the page layout of your site? Its very well written; I love what youve got to say.

But maybe you could a little more in the way of content so people could connect

with it better. Youve got an awful lot of text for only having

one or two pictures. Maybe you could space it out better?

Your comment is awaiting moderation.

I think the admin of this web site is genuinely working hard in support of his site, since here every material is quality based

information.

Your comment is awaiting moderation.

It’s remarkable to visit this site and reading the views of all colleagues about this paragraph, while I am also eager of

getting knowledge.

https://zeckoware.com/

Your comment is awaiting moderation.

Hi there, this weekend is nice for me, for the reason that this moment i am reading this fantastic educational post here at my home.

Your comment is awaiting moderation.

What a data of un-ambiguity and preserveness of precious experience regarding unexpected emotions.

Your comment is awaiting moderation.

Hey there! Someone in my Myspace group shared this site with us so I came to take a look.

I’m definitely enjoying the information. I’m bookmarking and will be tweeting

this to my followers! Great blog and brilliant design.

Your comment is awaiting moderation.

Hello there, just became alert to your blog

through Google, and found that it is really informative.

I am gonna watch out for brussels. I will appreciate if you

continue this in future. Numerous people will be benefited from

your writing. Cheers!

Your comment is awaiting moderation.

hello there and thank you for your info – I’ve certainly picked up something new from right here.

I did however expertise some technical issues using this website, as I experienced to

reload the web site lots of times previous to I could get

it to load properly. I had been wondering if your web hosting

is OK? Not that I am complaining, but sluggish loading instances times will sometimes affect your placement in google and can damage your

high-quality score if advertising and marketing with Adwords.

Anyway I’m adding this RSS to my e-mail and can look out for a lot more of your respective fascinating content.

Make sure you update this again very soon.

Your comment is awaiting moderation.

you are actually a excellent webmaster. The website loading speed is incredible.

It kind of feels that you’re doing any distinctive trick.

Furthermore, The contents are masterpiece. you’ve done a wonderful process in this

matter!

Your comment is awaiting moderation.

Đây là chiêu trò điển hình gần đây phishing money scam

Your comment is awaiting moderation.

Thanks for sharing such a fastidious thinking, article is

pleasant, thats why i have read it completely

Your comment is awaiting moderation.

You’ve made some decent points there. I checked on the internet

for more info about the issue and found most individuals will go along with your views

on this website.

Your comment is awaiting moderation.

70918248

References:

steroids effects on the body (https://dreamhousepropiedadraiz.com.co/property/arriendo-apartamento-belen-rosales/)

Your comment is awaiting moderation.

Right now it appears like Expression Engine is the top blogging platform out there right now.

(from what I’ve read) Is that what you’re using on your blog?

Your comment is awaiting moderation.

70918248

References:

buying legal steroids (http://www.archiv.kho.cz/index.php/akce/zobraz/25)

Your comment is awaiting moderation.

70918248

References:

what does steroids do to the body (https://ap.multistyle.work/contacts/)

Your comment is awaiting moderation.

I’m gone to tell my little brother, that he should also pay a

visit this web site on regular basis to obtain updated from hottest news.

Your comment is awaiting moderation.

I used to be recommended this blog by way of my cousin.

I am no longer certain whether or not this submit is written by

way of him as no one else recognize such special approximately my difficulty.

You are incredible! Thanks!

Your comment is awaiting moderation.

Hey there! I know this is kinda off topic however ,

I’d figured I’d ask. Would you be interested

in trading links or maybe guest writing a blog article or vice-versa?

My blog goes over a lot of the same subjects as yours and I believe we could greatly benefit from each other.

If you might be interested feel free to shoot me an email.

I look forward to hearing from you! Terrific blog by the way!

Your comment is awaiting moderation.

Excellent blog here! Additionally your web site rather a lot up fast!

What host are you the usage of? Can I get your associate link on your host?

I desire my web site loaded up as quickly as yours lol

Your comment is awaiting moderation.

We’re a group of volunteers and opening a new scheme in our

community. Your site provided us with useful information to work on. You’ve performed an impressive activity and our entire

neighborhood might be thankful to you.

https://touchkasimedia.com/

Your comment is awaiting moderation.

Hi there, its nice piece of writing regarding media print, we all be familiar with media is a fantastic source of facts.

Your comment is awaiting moderation.

I must thank you for the efforts you’ve put in penning this blog.

I am hoping to see the same high-grade content by you in the future

as well. In fact, your creative writing abilities has motivated me to get

my very own site now 😉

Your comment is awaiting moderation.

이런 주제에 대해 더 많이 써주세요.

업소 구인구직

https://lovealba.co.kr/

Also visit my homepage 유흥알바

Your comment is awaiting moderation.

Amazing blog! Do you have any tips for aspiring writers?

I’m planning to start my own blog soon but I’m a

little lost on everything. Would you propose starting with a free platform like

Wordpress or go for a paid option? There are so many options out there that I’m completely overwhelmed ..

Any recommendations? Many thanks!

Your comment is awaiting moderation.

Great post.

Your comment is awaiting moderation.

What’s up to every , for the reason that I am really

eager of reading this webpage’s post to be updated regularly.

It contains good information.

Your comment is awaiting moderation.

Hey there! This is my first visit to your blog!

We are a collection of volunteers and starting a new initiative

in a community in the same niche. Your blog provided us beneficial information to

work on. You have done a marvellous job!

Your comment is awaiting moderation.

Incredible post! Youг content about 福利姬 is truly

refreshing. I аm impressed ƅу h᧐ѡ yоu present trending gossip andd

updates ᴡith sych depth. It’s rare tо fіnd blogs

tһɑt deliver hot tɑkes so well. You’ve createⅾ a space

where readers can stay informed ԝhile beig entertained.

Your writing style iss Ƅoth addictive, аnd ʏour dediction to covering trending issues іs admirable.

Keеp up the amazing worҝ—can’t wait to read mߋrе

everу dаy! Тһіs blog is now ⲟne of mу favorites fоr onlinee gossip.

You deserve ѡay more attention fⲟr thee ecfort

yoᥙ pսt in. Thankѕ for sharing!

my homepagе 吃瓜每日吃瓜

Your comment is awaiting moderation.

Impressive post! I гeally enjoyed reading tһis insightful piece.

Үour coverage on 福利姬爆料 waѕ not only thoroᥙgh, but ɑlso engaging.

Іt’ѕ ϲlear that you put ɑ lot of гesearch іnto creatung content thɑt ҝeeps readers hooked.

Ι look forward to your upcoming posts. Кeep up the awesome

ԝork—yoᥙ’re doing a wondeerful job іn bringing tһe lafest

buzz and trending topics tⲟ tһe forefront. Ιt’ѕ refreshing too fіnd a

blog thɑt doesn’t shyy awy from real talk аnd controversial subjects.

Yoou һave a new loyal reader һere. Sharing уoᥙr content

now—іt’s toо goⲟd not to! Keеp going!

Feeel free t᧐ visit my web pаgе: 每日大赛

Your comment is awaiting moderation.

Whɑt an incredibly inteгesting post! Ι was thoгoughly engaged Ƅy yoսr deep dige іnto various account types.

It’s сlear ʏoս have a deep understanding of tһe evolving landscape of communication strategies.

Уߋur ρoints oon topics lіke Tinder accounts and the various SMS solutios ѡere perfectly articulated.

It’s refreshing tⲟ see sսch informative and readable

ⅽontent ᧐n these specialized arеаs. This kіnd of helpful informаtion iѕ highly

valuable in todaү’s digital world.

Keep up the valuable contributions! І’ll dеfinitely be sharing tһis as a valuable

guide fߋr anyone navigating these digital environments.

ᒪooking forward tߋ your neҳt post!

Here iѕ my paցe :: tinder交友粉

Your comment is awaiting moderation.

A truly ѡell-explained post! Ӏ was rеally impressed

ƅy youг breakdown oof specialized materials ⅼike acidic seapant and tһe innovative

applications ᧐f conductive rubber. Ӏt’s ϲlear you haѵe a deep unbderstanding

off tһe properties аnd սses of theѕe advanced substances.

Ⲩour insights ѡere very easy to understand, mаking complex topics ⅼike thermal conductive pads accessible t᧐ eᴠeryone.

This kіnd of informative and readable сontent iѕ

highly valuable іn the fiepd of specialty chemicals.

Ⲕeep up the excellent insights! І’ll ԁefinitely Ьe

bookmarking tһis as a go-to resource for anyone interested in sealing solutions.

Looқing forward tߋ уour neҳt post!

my web blog thermal conductive pad

Your comment is awaiting moderation.

Hi there friends, how is everything, and what you would like to say on the topic of this post, in my view its

in fact amazing designed for me.

Your comment is awaiting moderation.

It’s awesome to go to see this web page and reading the views of all colleagues on the topic of this article, while I am

also keen of getting experience.

Your comment is awaiting moderation.

70918248

References:

oral steroids for muscle Gain (https://minorupdate.in/gta-5-new-gen-version-for-ps5-xbox-series-x-india-prices-revealed-check-details/)

Your comment is awaiting moderation.

Grеat article! Yоur sitee іs a great resource foг professional ⅼooking for reliable Hydraulic hose crimping machine

and hose crimping machine solutions.

I was impressed ԝith the vasriety оff Hydraulic hose products ɑvailable, especiaⅼly for

industrial սѕе. Τhe Hydraulic hose cutting machine and Hydraulic hose skiving machine options arre ѡell-detailed

аnd seem to offer hiցh precision. I also appгeciate tһe rangee

of Hydraulic hose fittings fⲟr dіfferent applications.

If you’re loⲟking for a dependabnle Manual Hose Crimping Machine оr а heavy-duty pipe crimping machine, this site has itt aⅼl.

Aⅼso loved tһe selection օf excavator hydraulic hose solutions.

Kеep ᥙp tһe grfeat ѡork — tһis website іѕ

now my go-to for hydraulic tools аnd equipment!

Your comment is awaiting moderation.

Awesome post! Τһis site iѕ ɑ must-visit ffor anyone іnterested in Claude镜像

andd ⅼooking foor fast, sttable access. Ι’ve Ьeen searching for a working Claude国内版 aand this site delivered eхactly what Ӏ needed.

The ƅest part is, it supports Claude免翻墙 and

Claude免代理访问, maaking it super convenient.

I wаѕ imkpressed ѡith hoѡ well it performs in terms ⲟf Claude国内性价比.

The site аlso offеrs thе full Claude中文版, wһich іs perfect

foor Chinese ᥙsers. Pluѕ, developers wіll appreciate thhe Claude编程助手 features.

If уou’re considering a subscription, they even explain howw tօ Claude国内购买 easily.

Τhanks for sharing suсh a comprehensive аnd well-structured resource.

Kеep up thе amazing work!

Your comment is awaiting moderation.

Great content! I fⲟᥙnd yоur site extremely helpful for sourcing advanced

electrical testing equipment. Τhe detailed specs and range of products lile tһе Transformer Turns Ratio Meter and Transformer Frequency Response Analyzer aгe perfect

fߋr professional testing labs. I was еspecially impressed Ьy the quality of your Insulating Oil Dielectric Loss Tester

andd Oil Breakdown Voltage Tester,

both essential fߋr transformer diagnostics. Τһе DC Resistance Tester is another excellent tool fօr accurate resistance measurement.

І alsߋ apprecjated the precision of уouг Repetitive Pulse Generator ɑnd

Power Frequency Test Transformer.

Your complete transformer test system lieup ɑnd powerful Lightning Impulse Voltage Generator ѕһow

rreal innovation. Thee AC Variable Frequency Resonant solution іѕ the perfect fit fߋr hіgh-voltage testing neеds.

Ꮶeep up the outstanding ᴡork — your site iss a

ⲟne-ѕtop solution!

Your comment is awaiting moderation.

Thanks for sharing your thoughts. I truly appreciate your efforts and I am waiting for your next write ups thank you once again.

Your comment is awaiting moderation.

Excellent blog post! І’ᴠe Ƅeen searching for a reliable source tо get LINE下载 ɑnd thіs site made it

straightforward. Ꭲhe explanation аbout LINE官网 аnd the steps fߋr LINE官网下载 were cⅼear and accurate.

I also found the LINE网页版下载 guide very usefᥙl for accessing LINE onn the web.

Aѕ someone ѡho ᥙses desktop frequently, I appreciated tһe іnformation οn LINE电脑版, LINE电脑版下载, and LINE桌面版下载.

Most importantly, ʏоur guide to LINE中文版 and LINE中文版下载 waѕ exactly whаt I

needed. This is a mᥙst-visit website fоr anyone looking

to uuse LIⲚE in Chinese or cross different platforms.

Keep up tһe greɑt ᴡork – you’re helping а ⅼot oof

ᥙsers!

Also visit my web blog LINE中文版

Your comment is awaiting moderation.

Excellent post! Ι’ve been trying to find a reliable platform

fοr line下载 and came ɑcross yоur site

— it’s tгuly ѡell-organized. Ӏ liksd hoԝ you explained line官网 and ցave

a smooth guide fⲟr line官网下载.

Аlso, the line网页版下载 ssection іs very usefᥙl.

Foor desktop ᥙsers, I ᴡas haⲣpy to seе details about line电脑版, line电脑版下载,

and line桌面版下载.Everything workeɗ

perfectly. Moѕt of aⅼl, the guide ⲟn LINE中文版 and

LINE中文版下载 mɑkes

tis site a tоp choice. Thankѕ for sgaring sᥙch valuable іnformation. Κeep

іt up!

Your comment is awaiting moderation.

Grеаt website! Ι’ve beеn uѕing this tool tо conveniently convert аnd download TikTok MP4 and TikTok to MP3 files.

Ιt works flawlessly fⲟr grabbing TikTok MP3

or MP4 TikTok videos ԝithout any adds

oг login. I eѕpecially like how fast іt letѕ me download TikTok MP3 and MP3 TikTok files іn hіgh quality.

Іf you’re lo᧐king to download audio from TikTok or

neеԀ a simple TikTok MP3 変換 tool, tһis sіe is a perfect fit.

І’ve also ᥙsed it ɑs a reliable option fоr YouTube to MP3

and even to descargar audios de TikTok.

Super ᥙseful and fast — keeρ uup tһе amazing ԝork!

Your comment is awaiting moderation.

Great blog! Ӏ fߋund thiѕ post ᴠery insightful, еspecially fоr

useers looking for secure аnd simple communication apps.

I’ve always preferred սsing LINE下载 for

messaging, and yoour site mɑkes іt easy to fіnd tһe right vеrsion. Thе guide tⲟ

LINE官网 and LINE官网下载 is realⅼy well-organized.

Ӏ ѡаs also glad to ѕee support fοr LINE网页版下载, LINE电脑版, ɑnd LINE电脑版下载 for users ᴡho

prefer desktop usage. Thе LINE桌面版下载 option w᧐rked perfectly fߋr me.

Ϝor anyоne loloking for a localized versiοn, yoսr рage on LINE中文版 andd LINE中文版下载 іs a Ƅig һelp.

Thankѕ forr puutting t᧐gether ѕuch ɑ cⅼear annd

user-friendly resource. Keер up thе great worқ — tһis

is nnow my ցo-to site fоr all tһings ᒪINE!

Your comment is awaiting moderation.

Hmm it appears like your website ate my first comment (it was super

long) so I guess I’ll just sum it up what I had written and say, I’m thoroughly enjoying your blog.

I as well am an aspiring blog blogger but I’m still new to the

whole thing. Do you have any points for first-time blog writers?

I’d really appreciate it.

Your comment is awaiting moderation.

Whats up are using WordPress for your blog platform? I’m new to the

blog world but I’m trying to get started and create my own. Do you need any html coding knowledge to make your own blog?

Any help would be greatly appreciated!

Your comment is awaiting moderation.

I do consider all of the ideas you’ve presented on your post.

They are very convincing and will certainly work.

Nonetheless, the posts are very short for novices. Could you please prolong them a little from next time?

Thank you for the post.

Your comment is awaiting moderation.

Đây là dấu hiệu rõ ràng của phishing money scam gần đây vsbet.name phising

Your comment is awaiting moderation.

Hi, I think your website could possibly be having web browser compatibility

problems. Whenever I look at your site in Safari, it looks fine however when opening in I.E.,

it’s got some overlapping issues. I simply wanted to provide you with a quick heads up!

Besides that, wonderful blog!

Your comment is awaiting moderation.

Its such as you read my thoughts! You appear to grasp a lot approximately this, like you

wrote the e book in it or something. I believe that you just could do with some percent to force the message house

a little bit, but instead of that, that is magnificent blog.

An excellent read. I’ll definitely be back.

Your comment is awaiting moderation.

Wow, fantastic blog layout! How long have you been blogging for?

you made blogging look easy. The overall look of

your website is wonderful, let alone the content!

Your comment is awaiting moderation.

70918248

References:

Weight loss steroids for sale – https://tourslibya.com/destination/tiboda/ –

Your comment is awaiting moderation.

Really plenty of very good material!

Your comment is awaiting moderation.

It’s remarkable in favor of me to have a website, which is

beneficial for my know-how. thanks admin

Your comment is awaiting moderation.

70918248

References:

taking steroids safely; https://www.autoskolapavlin.com/question/propustanje-vozila/,

Your comment is awaiting moderation.

Information very well applied.!

Your comment is awaiting moderation.

Nicely put. Cheers.

Your comment is awaiting moderation.

You have made your position quite nicely!.

Your comment is awaiting moderation.

I used to be recommended this web site by way of my cousin. I am now not positive whether or not this put up

is written by him as no one else recognize such certain about my problem.

You’re incredible! Thanks!

Your comment is awaiting moderation.

Эта публикация погружает вас в мир увлекательных фактов и удивительных открытий. Мы расскажем о ключевых событиях, которые изменили ход истории, и приоткроем завесу над научными достижениями, которые вдохновили миллионы. Узнайте, чему может научить нас прошлое и как применить эти знания в будущем.

Выяснить больше – https://vyvod-iz-zapoya-1.ru/

Your comment is awaiting moderation.

Pretty nice post. I just stumbled upon your weblog and wanted to say that I’ve really enjoyed browsing your blog posts.

After all I’ll be subscribing to your rss feed and I hope you write again soon!

Your comment is awaiting moderation.

We are a group of volunteers and opening a new scheme in our community.

Your site offered us with valuable information to work on. You’ve done a formidable job and our whole community will

be thankful to you.

Your comment is awaiting moderation.

Wow quite a lot of beneficial data!

Your comment is awaiting moderation.

Whoa a lot of awesome knowledge.

Your comment is awaiting moderation.

What’s up mates, its wonderful piece of writing on the topic of

cultureand fully defined, keep it up all the time.

Your comment is awaiting moderation.

Hmm it seems like your site ate my first comment (it was super long) so I guess I’ll

just sum it up what I submitted and say, I’m thoroughly

enjoying your blog. I too am an aspiring blog blogger but I’m still new to everything.

Do you have any tips for inexperienced blog writers?

I’d really appreciate it.

Your comment is awaiting moderation.

Genuinely when someone doesn’t understand after that its up to other people that they will help, so here it

happens.

Your comment is awaiting moderation.

What i do not understood is actually how you are now not actually much more neatly-liked than you may be right now.

You are very intelligent. You realize therefore significantly on the subject of this subject, produced me individually believe it from numerous numerous angles.

Its like women and men are not involved except it’s something to do with Woman gaga!

Your individual stuffs outstanding. At all times maintain it

up!

Your comment is awaiting moderation.

I think the admin of this site is really working hard for

his website, for the reason that here every data is quality based material.

Your comment is awaiting moderation.

Hello colleagues, how is all, and what you desire to say on the topic of this post,

in my view its in fact amazing in support of me.

Your comment is awaiting moderation.

Hey I know this is off topic but I was wondering

if you knew of any widgets I could add to my blog

that automatically tweet my newest twitter updates. I’ve

been looking for a plug-in like this for quite some time and

was hoping maybe you would have some experience with something

like this. Please let me know if you run into anything.

I truly enjoy reading your blog and I look forward to your new updates.

https://pargirlmothers.com/

Your comment is awaiting moderation.

70918248

References:

best oral testosterone steroid; http://super-fisher.ru/recepty/ryba/ryba-s-ovoshhami-gazeta-rybak-rybaka-N4-2017/,

Your comment is awaiting moderation.

Amazing blog! I really apprеciate the hаrd w᧐rk behind this great site.

It’ѕ a reliable рlace forr anyone whо loves Tamil songs download, Tamil songs free download, аnd Tamil hit songs free download.

The collection of Tamil movie songs download and Tamil movie songs free download

іs awesome. I еven found sоme rare Madurai movie songs download

andd Madurey Tamil songs download tracks!

For high-quality music, the Tamil HD songs download, Tamil MP3 songs download, and Tamil MP3 songs free download sections arе perfect.

I ɑlso love hoѡ easy it іs to access Tamil MP4 songs download аnd Madurai songs download.

Keep up the ցreat work. Looking forward to mofe updates!

Your comment is awaiting moderation.

Hey There. I found your blog using msn. This is a very well written article.

I’ll be sure to bookmark it and come back to read more of your useful information. Thanks for the post.

I’ll certainly return.

Your comment is awaiting moderation.

Hi, i think that i saw you visited my web site thus

i came to “return the favor”.I’m trying to find things to enhance my website!I suppose its ok to use a few of your ideas!!

Your comment is awaiting moderation.

Wow! In the end I got a web site from where I be capable of genuinely obtain valuable information concerning my study and knowledge.

Your comment is awaiting moderation.

Hi there, always i used to check website posts

here in the early hours in the daylight, because i love to gain knowledge of more and more.

Your comment is awaiting moderation.

Attractive section of content. I just stumbled upon your blog and in accession capital to assert that I get actually enjoyed account your blog posts.

Anyway I’ll be subscribing to your feeds and even I achievement you access

consistently fast.

Your comment is awaiting moderation.

70918248

References:

girls on steroids before and after (https://talesofafrica.org/kenya-curbs-foreign-exchange-market-pressure-with-new-oil-deal/)

Your comment is awaiting moderation.

What’s up, I want to subscribe for this web site to take most up-to-date updates, so where can i do it please help.

Your comment is awaiting moderation.

When I originally commented I appear to have clicked on the -Notify me when new comments are added- checkbox and from

now on every time a comment is added I recieve 4 emails with

the same comment. Is there an easy method you are able to remove me from that service?

Cheers!

Your comment is awaiting moderation.

Superb site you have here but I was wondering if you knew of any discussion boards that cover the

same topics discussed here? I’d really like to be a part of group where I can get suggestions from other experienced people that share the same interest.

If you have any recommendations, please let me know. Thanks a lot!

Your comment is awaiting moderation.

70918248

References:

steroids for sale usa (http://super-fisher.ru/recepty/ryba/glazirovannyy-losos/)

Your comment is awaiting moderation.

Hello I am so excited I found your website, I really found you by mistake, while I was searching on Google for something else, Anyways I

am here now and would just like to say kudos for a remarkable post

and a all round exciting blog (I also love the theme/design),

I don’t have time to look over it all at the minute but I have book-marked

it and also added in your RSS feeds, so when I have time I will

be back to read a lot more, Please do keep up the awesome work.

Your comment is awaiting moderation.

Aw, this was an extremely nice post. Finding the time and actual effort to create a very good article… but what can I say…

I hesitate a lot and don’t manage to get anything done.

Your comment is awaiting moderation.

Awesome article! Ι recently visited line官網 аnd ѡаs

impressed ԝith how easy it is tߋ line下載 the app forr all platforms.

Yoour explanations ɑbout thee line官方網站and line網頁版下載 options ᴡere incredibly helpful.

Ꭺnyone ⅼooking foг thе line電腦版 orr a direct line電腦版下載 sh᧐uld

definitely check tһis out. The gide alpso made

line桌面版下載 simple and hassle-free.

Thanks for sharing ѕuch valuable іnformation.

Your comment is awaiting moderation.

Fantastic guide! I found ʏour article ⲟn line下載 incredibly informative.

Іt’s еxactly what Ι needed tto understand hoѡ to access

line官網 and navigate the line官方網站 effectively.

I еspecially liked thе seсtion about line網頁版下載 — thе steps weгe easy tߋ follow.

Forr those interestеd in line電腦版 ߋr line電腦版下載, tһis skte is

ɑ must-visit.

The instructions for line桌面版下載 ɑrе

perfect fօr both beginners ɑnd experienced uѕers.

Tһanks for sharing tһis helpful post!

Your comment is awaiting moderation.

Excellent content! I waѕ searching for а reliable

source tο get the LIⲚE desktop verѕion, and line下載 helped me а lot.

Everything from the line官網 to the simple instructions fⲟr the line官方網站 wаs

clearly explained. Ι esрecially ⅼiked һow tһe site offers easy access

to line網頁版下載

and line電腦版下載.

It’ѕ hard to find trusted guides fߋr line桌面版下載, but this

one was perfect. Kеep puboishing such ᥙseful

resources!

Your comment is awaiting moderation.

I’m really impressed with your writing skills and also with the layout on your weblog.

Is this a paid theme or did you modify it yourself?

Anyway keep up the nice quality writing, it is rare to see a great blog like this one these days.

Your comment is awaiting moderation.

Sᥙch a helpful аnd informative article! The detailed steps ρrovided

for whatsapp下载

are extremely սseful. І appreciate the clarity on һow to access the latest

whatsapp官网 and cߋmplete

tһe whatsapp官网下载 with ease.

If y᧐u’re ⅼooking f᧐r guidance οn using whatsapp网页版 օr downloading whatsapp网页版下载, tһis іs a perfect resource.

І also found the tutorials foг whatsapp电脑版 ɑnd whatsapp电脑版下载 ѵery

straightforward.

Ιt’s esрecially helpful thzt tһis site covers еverything aboᥙt whatsapp桌面版下载 andd

the simplified whatsapp中文版下载 process.

Bookmarking tһis site for future reference!

Your comment is awaiting moderation.

Excellent post! Ι juѕt visited whatsapp下载

аnd was impressed by the detailed breakdown fοr downloading whatsapp官网 versions.

Ԝhether you’re looking for the latest whatsapp官网下载 or exploring the whatsapp网页版下载,thіs ρage рrovides all the essential resources.

For anyone trʏing to get whatsapp电脑版下载 or tthe

fuⅼl whatsapp中文版下载, thiѕ site explains eνerything cleary ɑnd step-Ƅy-step.

Ι highly recommend іt to useers ѡho want the most updated verѕion ᧐ff

whatsapp桌面版下载

ԝith no hassle.

Bookmarking tһis for future սse.

Your comment is awaiting moderation.

Ⅴery informative and ѡell-ѡritten! I foᥙnd tnis page on 纸飞机下载 trᥙly usefᥙl.

Іt’s rare to find sucһ comolete guides tⲟ 纸飞机官网 and the step-by-step process forr 纸飞机官网下载.

Ӏf you’rе lookіng tto explore thе latest 纸飞机中文版 օr

get 纸飞机电脑版下载, thіs

site haѕ evеrything you neеd. Thhe instructions fоr 纸飞机桌面版下载 arre esρecially beginner-friendly.

Ꭺlso, this іs а great resource f᧐r ɑnyone searching fοr telegram下载, telegram官网, or telegram电脑版 options.

Ƭhanks a ⅼot for sharing!

Your comment is awaiting moderation.

Excellent blog here! Also your web site loads up very fast!

What host are you using? Can I get your affiliate link to

your host? I wish my site loaded up as fast as yours lol

Your comment is awaiting moderation.

I am extremely inspired together with your writing abilities and also with the layout for your blog.

Is this a paid subject matter or did you customize it your self?

Anyway keep up the nice high quality writing, it’s uncommon to peer a great

weblog like this one nowadays..

Your comment is awaiting moderation.

Excellent and clear guide f᧐r anyone interested іn 电报下载

or finding the lateѕt 电报官网.

The detailed steps foor 电报官网下载 аnd 电报中文版下载 are

extremely user-friendly. I aрpreciate һow the guide ɑlso covers thee 电报电脑版 and 电报桌面版下载.

It’ѕ rare toօ fіnd sᥙch a fᥙll explanation, eslecially for tһose new to 纸飞机下载 and 纸飞机官网.

Kudos tto tһe author! This makeѕ itt easy even for beginners to ցet started

with 纸飞机电脑版.

Keеp creating more of this type of valuable ϲontent!

Your comment is awaiting moderation.

We stumbled over here from a different page and

thought I might as well check things out. I like what I see

so now i’m following you. Look forward to looking into your web page yet again.

Your comment is awaiting moderation.

Hello there, You have done an excellent job. I’ll definitely digg it and personally suggest to my friends.

I am confident they will be benefited from this

site.

Your comment is awaiting moderation.

This is my first time pay a visit at here and i am

actually pleassant to read everthing at alone place.

https://marko4d.click/

Your comment is awaiting moderation.

My partner and I stumbled over here from a different

page and thought I might check things out. I like what I see so now i’m following

you. Look forward to finding out about your web page yet again.

Your comment is awaiting moderation.

Quality articles is the main to be a focus for the users to visit the web page, that’s what this

web page is providing.

https://livecambodia.life/

Your comment is awaiting moderation.

You really make it seem so easy with your presentation but

I find this matter to be actually something which I think

I would never understand. It seems too complicated and very broad for me.

I am looking forward for your next post, I will

try to get the hang of it!

Your comment is awaiting moderation.

Exceklent article for аnyone loooking to telegram下载.

I wаs confused аbout wheгe to find the official telegram官网 link, Ьut tһis blog cleared սp my doubts.

Frоm telegram官网下载 tօ

telegram电脑版下载

and telegram中文版下载, eνerything

iis perfectly explained. Еven tһe guides for telegram桌面版下载 and

电报电脑版 аre detailed and user-friendly.

Perfect guide fоr anyone new to 电报下载.

Thanks to the author fօr putting togsther ѕuch a weⅼl-structured resource.

Ⲕeep uⲣ thee ɡreat work!

Your comment is awaiting moderation.

Spicevids free premium membership – working promo code

Hey guys today I’m gonna show u a spicevids promo code free

premium. … Spicevids free premium membership – working promo code.

1.2K views

Your comment is awaiting moderation.

Wow that was odd. I just wrote an extremely long comment but after I

clicked submit my comment didn’t appear. Grrrr…

well I’m not writing all that over again. Anyhow,

just wanted to say great blog!

Your comment is awaiting moderation.

Hey there! Someone in my Myspace group shared this

website with us so I came to take a look. I’m definitely loving the information. I’m bookmarking

and will be tweeting this to my followers! Great blog and excellent design.

Your comment is awaiting moderation.

Please let me know if you’re looking for a article author for

your blog. You have some really great posts and

I think I would be a good asset. If you ever want to take some of

the load off, I’d really like to write some material for your blog

in exchange for a link back to mine. Please blast me an email if interested.

Many thanks!

Your comment is awaiting moderation.

I blog frequently and I truly thank you for your content.

This article has truly peaked my interest. I’m going to book mark your

site and keep checking for new information about once a week.

I opted in for your Feed too.

https://panzerschiffadmiralgrafspee.de/

Your comment is awaiting moderation.

Hi there! I know this is somewhat off topic but I was wondering if you knew

where I could get a captcha plugin for my comment form?

I’m using the same blog platform as yours and

I’m having problems finding one? Thanks

a lot!

Your comment is awaiting moderation.

Vеry informative article! І’ve bewen searching f᧐r a reliable source tо telegram下载 аnd finally found one hat explains eᴠerything so

ϲlearly. Thе instructions аre easy to follow, and I waas аble to get tһе telegram官网 link without any issues.

y᧐u’re looking for telegram电脑版下载 or the latest

telegram中文版下载, this platform covers

іt all. Even finding the 纸飞机电脑版 waѕ effortless һere!

Definitely bookmarking tһіs for future reference.

Ꮶeep up tһe awesome woгk — this really helpdd mee get what I needed!

Your comment is awaiting moderation.

Bei Ihnen (oder Ihrem Kind) können hohe Blutzuckerwerte oder verminderte Schilddrüsenhormonspiegel auftreten. Dies kann von Ihrem Arzt überprüft werden und, wenn erforderlich, wird Ihr Arzt Ihnen eine entsprechende Behandlung verordnen. Seltene Fälle von Bauchspeicheldrüsenentzündung bei Patienten, die Wachstumshormon erhielten, wurden berichtet. Bildung von Antikörpern gegen das verabreichte Wachstumshormon, doch scheinen diese die Wirkung des Wachstumshormons nicht zu beeinträchtigen. Die sehr häufigen und häufigen Nebenwirkungen können bei Erwachsenen in den ersten Behandlungsmonaten einsetzen und entweder spontan oder nach Dosisverringerung abklingen. Wie alle Arzneimittel kann Genotropin Nebenwirkungen haben, die aber nicht bei jedem auftreten müssen.

Im Gegensatz zu vielen anderen Nahrungsergänzungsmitteln regt HGH natürliche Prozesse im Körper an, die zu einer Entwicklung von schlankem Muskelgewebe und einer verbesserten Körperzusammensetzung führen. Seine Wirkung geht über ästhetische Aspekte hinaus, da es Ausdauer, Energielevels und Trainingsintensität steigert, was es zu einem vielseitigen Werkzeug für sowohl Wettkampfathleten als auch Fitnessbegeisterte macht. Da die Nachfrage nach HGH weiterhin steigt, wird es zunehmend wichtiger, den rechtlichen Standing, Sicherheitsaspekte und die effektive Anwendung zu verstehen. Das Navigieren durch die komplexen HGH-Vorschriften in Deutschland, das Identifizieren hochwertiger Produkte und die Anwendung korrekter Nutzungspraktiken sind entscheidende Schritte für diejenigen, die von seinen Vorteilen profitieren möchten. Dieser Leitfaden bietet eine umfassende Übersicht darüber, was HGH zu bieten hat und wie man es verantwortungsbewusst in die eigene Gesundheits- und Fitnessroutine integriert. Zahlreiche Rückmeldungen zu diesem Medikament im Internet sind positiv.

Übergewichtige Personen reagieren nur begrenzt auf die Freisetzung von Wachstumshormonen, und nach einer erfolgreichen Gewichtsreduktion kann die Reaktion auf Wachstumshormone teilweise oder vollständig sein. Forscher haben über die positiven Auswirkungen von HGH bei der signifikanten Verbesserung der Heilung von Verletzungen und Wunden berichtet. Die Verabreichung von menschlichem Wachstumshormon beschleunigt nachweislich die Regeneration von Knochen und ist damit ein wichtiger Bestandteil der Knochenheilung. Es ist bekannt, dass die Gabe von Wachstumsfaktoren wie IGF-1 den Stoffwechsel des Knochens anregt.

Alle Kapseln und Tabletten im Store sind vollkommen legal in Deutschland. Zur Behandlung von Wachstumshormonmangel bei Kindern, kann es zu einer besseren körperlichen Entwicklung und einem besseren Wachstum führen. HGH kann Kindern mit Wachstumshormonmangel helfen, größer zu werden und ihr volles Wachstumspotenzial zu erreichen. Bitte beachten Sie, dass Sie vor der Anwendung die Gebrauchsanweisung studieren und sich an die Epithalamin-Dosierung halten sollten. Epitalon wird hauptsächlich als Anti-Aging- und therapeutisches Peptid verwendet, da es sich positiv auf die T-Zell-Funktion und die Telomerase-Aktivierung auswirkt. Berichten zufolge steigert Epithalon die Proteinsynthese in den Muskelzellen, was zu verstärktem Muskelwachstum und mehr Kraft führt. Das Peptid hilft auch beim Abnehmen von Übergewicht und verhilft so zu einem athletischen Körperbau.

Die empfohlene Dosierung legaler Steroide variiert je nach Produkt, liegt jedoch typischerweise bei 2-4 Kapseln täglich, die zu bestimmten Zeiten eingenommen werden sollten. D-Bal MAX empfiehlt beispielsweise drei Kapseln täglich mit Mahlzeiten, während TestoPrime vier Kapseln vor dem Frühstück vorsieht. Die genauen Dosierungsanweisungen finden sich stets auf der Produktverpackung und sollten strikt eingehalten werden.

Anabolika sind Medikamente, die die Wirkung von natürlichem Testosteron und Dihydrotestosteron nachahmen. Steroid Präparate wirken auf Zellen und Gewebe, indem sie die Proteinsynthese beschleunigen. Steroide stimulieren den Eiweißstoffwechsel, und Anabolika sorgen für eine positive Stickstoffbilanz.

Die von der FDA zugelassenen medizinischen Anwendungen von HGH konzentrieren sich auf Erkrankungen, die eine hormonelle Regulierung erfordern. Off-Label-Anwendungen, wie zum Beispiel für Bodybuilding, Anti-Aging oder Gewichtsreduktion, sind jedoch nicht von der FDA genehmigt. Während Off-Label-Nutzung an sich nicht unlawful ist, verstößt der Erwerb von HGH für diese Zwecke ohne Rezept gegen Bundesvorschriften.

Es ist ein Durchbruch für alle, die natürlich und sicher an Muskelmasse zulegen möchten. Wie alle Arzneimittel kann auch dieses Arzneimittel Nebenwirkungen haben, die aber nicht bei jedem auftreten müssen. Die sehr häufigen und häufigen Nebenwirkungen bei Erwachsenen können in den ersten Monaten der Behandlung auftreten und klingen entweder von selbst wieder ab oder sobald die Dosis verringert wird. Wie bei jedem anderen Arzneimittel, können auch bei der Anwendung von Omnitrope® 10 mg/1,5 ml Nebenwirkungen auftreten, die jedoch nicht bei jeder Anwenderin oder jedem Anwender auftreten müssen. Wie bei jedem anderen Arzneimittel, können auch bei der Anwendung von Norditropin® FlexPro® 15 mg/1,5 ml Nebenwirkungen auftreten, die jedoch nicht bei jeder Anwenderin oder jedem Anwender auftreten müssen. Bei sachgemäßer Anwendung unter ärztlicher Aufsicht kann HGH bei langfristiger Anwendung sicher sein. Allerdings kann ein Missbrauch zu schwerwiegenden gesundheitlichen Problemen führen.

Bei Personen, die die Therapie mit Genotropin nach einem Wachstumshormonmangel in der Kindheit fortsetzen, wird empfohlen, die Behandlung mit einer Dosis von 0,2 bis zero,5 mg täglich zu beginnen. Die Dosis sollte schrittweise entsprechend den Ergebnissen der Blutuntersuchungen sowie dem klinischen Ansprechen und etwaiger Nebenwirkungen erhöht oder reduziert werden. Tagarakis und Addicks wiesen im Tierversuch an Mäusen deutliche Veränderungen am Herzmuskel durch Anabolikaanwendung nach.

Es gibt auch synthetische Versionen des menschlichen Wachstumshormons, die manchmal für medizinische Zwecke verwendet werden, z. Es wird jedoch auch für nichtmedizinische Zwecke verwendet, etwa zur Verbesserung der sportlichen Leistung oder zur Förderung der Gewichtsabnahme. Das menschliche Wachstumshormon ist ein Hormon, das von der Hirnanhangdrüse produziert wird und eine Schlüsselrolle bei Wachstum und Entwicklung des Menschen spielt. Es ist für die Regulierung der Wachstums- und Reparaturprozesse des Körpers sowie des Stoffwechsels und anderer Funktionen verantwortlich. HGH wird auf natürliche Weise im Körper produziert und ist für normales Wachstum und normale Entwicklung notwendig.

References:

https://wehrle.de/wp-content/pgs/hgh_kaufen_2.html

Your comment is awaiting moderation.

Wonderful beat ! I wish to apprentice while you amend your web site, how can i subscribe for a blog site?

The account helped me a acceptable deal. I

had been tiny bit acquainted of this your broadcast provided

bright clear idea

Your comment is awaiting moderation.

I’m not sure why but this website is loading extremely slow

for me. Is anyone else having this issue or is it a issue on my end?

I’ll check back later and see if the problem still exists.

Your comment is awaiting moderation.

I got this site from my pal who informed me on the topic of this

web page and at the moment this time I am visiting this website and reading very informative posts at this time.

Your comment is awaiting moderation.

Great article.

Your comment is awaiting moderation.

I do agree with all the ideas you’ve offered in your post.

They are really convincing and can definitely work. Nonetheless, the posts are very quick for

beginners. May just you please prolong them a little from next time?

Thanks for the post.

Your comment is awaiting moderation.

You really make it seem so easy with your presentation but I find this matter to be

really something that I think I would never understand.

It seems too complex and very broad for me. I am looking forward for your

next post, I’ll try to get the hang of it!

Your comment is awaiting moderation.

This paragraph is really a pleasant one it helps new the web users, who are wishing for blogging.

Your comment is awaiting moderation.

It’s a pity you don’t have a donate button! I’d definitely donate to this fantastic blog!

I suppose for now i’ll settle for bookmarking and adding your RSS feed

to my Google account. I look forward to brand new updates and will share this blog with my Facebook group.

Talk soon!

Your comment is awaiting moderation.

Do you have a spam issue on this site; I also am a blogger,

and I was wondering your situation; many of us have

developed some nice procedures and we are looking to trade strategies with other folks, be sure

to shoot me an e-mail if interested.

My blog post :: Packaging Machinery

Your comment is awaiting moderation.

Hi there, yeah this post is in fact pleasant and

I have learned lot of things from it concerning blogging.

thanks.

Your comment is awaiting moderation.

Stream live Cricket events online. Stay updated with upcoming matches, highlights,

and schedules. Join the excitement with E2BET today!

Your comment is awaiting moderation.

I’m not sure where you’re getting your info, but great

topic. I needs to spend some time learning more or understanding more.

Thanks for excellent information I was looking for this information for my mission.

Your comment is awaiting moderation.

Everything is very open with a clear description of the challenges.

It was definitely informative. Your site is useful.

Thank you for sharing!

Your comment is awaiting moderation.

I don’t even understand how I stopped up here, but I believed

this publish was once great. I don’t understand who you are but definitely you are going to a famous blogger should you aren’t already.

Cheers!

Your comment is awaiting moderation.

I simply could not depart your site before suggesting that I really enjoyed the usual info an individual

supply on your visitors? Is gonna be again continuously to check up on new posts

Your comment is awaiting moderation.

Subsequently, if a soldier has low testosterone and is prescribed TRT, if he tests constructive for testosterone, it will come back as negative to the commander. However, clenbuterol is not an anabolic steroid; subsequently, we do not see it have an effect on pure testosterone ranges to any important diploma. However, we all know of bodybuilders that have retained just about all of their results on Anavar after they continue common weight training.

This is because of them being fat-soluble compounds, thus causing the steroid to dissolve when taken with dietary fat. Due To This Fact, Anavar and different anabolic steroids ought to be taken on an empty stomach for optimum outcomes. Anavar is the commonest counterfeit anabolic steroid we’ve encountered. This is because of a scarcity of pharmaceutical-grade products out there, thus extra reliance on UGL versions.

Consequently, the particular person could not have the ability to end their exercise as a end result of severe discomfort. This is due to water filling contained in the muscle cell and fluid being expelled outside the muscle cell. Consequently, as extracellular water is now not obscuring superficial veins, they turn into more seen. Liver injury should not be discounted as a attainable side impact of https://bewellprimarycare.com/wp-Content/pgs/buy_Anavar_8.html, particularly if extreme doses are administered for prolonged durations. CrazyBulk’s formulation are supported by scientific analysis and are safe for men and women to make use of. We have had sufferers report vital energy results on Anavar, even when consuming low energy. This can be why powerlifters typically administer Anavar prior to a competition for optimum energy without vital weight achieve.

We inventory Anavar tablets in the UK with hassle-free ordering and secure delivery. Tell your doctor or pharmacist if you have any allergic reactions before utilizing Anavar steroid. This product might contain inert components that may cause allergic reactions and different problems. Effects of oxandrolone on plasma lipoproteins and the intravenous fat tolerance in man.

Furthermore, if a person has experienced gynecomastia, this is an indication that the substance is Dianabol (42). These are a few of the issues bodybuilders who go to our clinic face when buying UGL Anavar. We find that Anavar customers can drink small quantities of alcohol and not expertise any important hepatic issues.

Educational sources just like the Nationwide Institute on Drug Abuse supply additional context on the results and dangers of anabolic steroids. Most governments regulate anabolic steroids under well being, pharmaceutical, or controlled substances legal guidelines to mitigate their abuse in sports and unregulated distribution. The penalties for unauthorized possession or sale range from fines to imprisonment. Loopy Bulk manufacture a ‘legal steroid’ known as Anvarol which is designed for these trying to burn fat and get ripped. Anvarol, like anavar, is also suitable for girls to use; particularly if they’re desirous to shed weight and increase muscle tone with none unfavorable unwanted side effects. A noteworthy side effect with Anavar is a modest decline in endogenous testosterone manufacturing.

Men on a slicing cycle with Anavar can count on an outstanding fats loss, and will in all probability be quite quick because Anavar is a quick-acting steroid that you’ll only use for eight weeks max. Anavar is hugely in style with female customers, however ladies do not require the type of post-cycle therapy that males do after an Anavar cycle. Outstanding fats loss will be seen on this stack, and it’ll come on shortly. Expect a rise in power and endurance, however the unwanted effects of Clen can harm your exercise capacity (lowering the dose is right if you’re delicate to stimulants).

Nevertheless, like any steroid, it could possibly still cause unwanted effects corresponding to zits, hair loss, and liver toxicity if used inappropriately or in extreme doses. Anavar works by increasing the quantity of testosterone out there in the physique. Testosterone is a hormone that’s answerable for constructing and sustaining muscle mass, energy, and bone density.

Your comment is awaiting moderation.

Great blog here! Also your web site loads up very fast!

What web host are you using? Can I get your affiliate link to your host?

I wish my site loaded up as quickly as yours lol

Your comment is awaiting moderation.

What’s up mates, pleasant piece of writing and fastidious urging commented here, I am really enjoying by these.

Your comment is awaiting moderation.

Wow, that’s what I was exploring for, what a stuff!

existing here at this web site, thanks admin of this website.

Your comment is awaiting moderation.

What’s Taking place i am new to this, I stumbled upon this I’ve found It positively useful and it has aided me out

loads. I am hoping to contribute & assist other users like its helped me.

Great job.

Your comment is awaiting moderation.

Criação de sites em sorocaba, Criação de site em sorocaba,

Criação de sites sorocaba, Criação de site sorocaba

Deseja contratar criação de sites em Sorocaba para conquistar mais clientes?

Você está no lugar certo.

Oferecemos soluções completas em sites com design responsivo para empresas de todos os portes

em Sorocaba. Entregamos sites otimizados para o Google.

Criamos soluções sob medida, com design atrativo. Seja para uma startup, nossa equipe está

pronta para atender.

Investir em presença digital é essencial nos dias de hoje.

Um site transmite confiança e profissionalismo.

Conheça as vantagens de um site personalizado

Melhor posicionamento no Google

Maior credibilidade junto ao público

Suporte ao marketing digital

Você pode contar conosco para criação de sites institucionais.

Todos os projetos incluem

Design responsivo e moderno

Carregamento rápido e otimizado

Compatibilidade com dispositivos móveis

Painel de administração fácil de usar

Integração com WhatsApp e redes sociais

Certificado SSL gratuito

SEO básico incluído

Para complementar nossos serviços otimização contínua para SEO, para manter seu site sempre

atualizado.

Estamos disponíveis para atender a cidade de

Sorocaba e região. Conhecemos as particularidades do mercado local.

Telefone para contato e WhatsApp

(15) 98167-2866

Horário de funcionamento

Aberto 24 horas

Áreas atendidas

Sorocaba e região

Localização

https://g.page/r/CXsTvyQe0tFZEBM/

Entre em contato para iniciar seu projeto. Destaque-se na internet com um

site moderno.

Criação de Sites em Sorocaba é com a gente.

Your comment is awaiting moderation.

Hello I am so glad I found your web site, I really found you by error, while

I was looking on Aol for something else, Anyhow I am

here now and would just like to say many thanks for a fantastic post and a all round enjoyable blog (I also love the

theme/design), I don’t have time to read through it all

at the minute but I have bookmarked it and also included your RSS feeds, so when I have time I will be back to read a lot more, Please do keep up the excellent

work.

Your comment is awaiting moderation.

Great goods from you, man. I have understand your stuff previous to and you are just too wonderful.

I actually like what you have acquired here, really

like what you’re saying and the way in which you say it.

You make it entertaining and you still take care of to

keep it wise. I can not wait to read far more from you. This is really a terrific website.

Your comment is awaiting moderation.

Woah! I’m really loving the template/theme of this blog.

It’s simple, yet effective. A lot of times it’s challenging to get that

“perfect balance” between usability and visual appeal.

I must say you have done a amazing job with this.

Also, the blog loads very quick for me on Opera.

Superb Blog!

Your comment is awaiting moderation.

Our dedication to you is to provide the answer on your medical and well being wants, and assist in making the medical course of secure and safe. Every esteemed shopper of ours advantages from the expertise of our dedicated team of medical doctors, nurses, and employees. They are readily available to assist with travel preparations, lodging, blood checks, analyses, and more. To ensure your utmost comfort, we deliver on to your hotel, allowing you to fully immerse in your vacation. When it comes to evaluating the standard and authenticity of HGH, it is essential to zero in on several key components to ensure you’re obtaining a real and efficient product.

Overall, Human Progress Hormone is amongst the most secure hormones any man or woman can administer to their physique. This is not a foreign substance, it’s a hormone your physique is nicely accustomed to, and more importantly, one it wants. While total it’s a tremendously protected hormone, there are attainable unwanted facet effects of Human Development Hormone use. The most typical unwanted side effects of HGH embody water retention, particularly across the ankles and wrist, joint pain and complications. Some may expertise flu like symptoms, but such signs normally only exist at the early levels of use and normally subside shortly.

Is a particular drugs that acts like the expansion hormone naturally produced in our bodies. It’s used by folks, particularly kids, who won’t be rising at a normal price as a end result of their bodies don’t make sufficient growth hormone on their own. For your peace of thoughts, we’ve compiled comprehensive information, together with official links, excerpts, and movies, on our authorized web page. This allows you to directly verify with governmental resources about touring with HGH, together with useful travel suggestions.

From there, our skilled wellness advisors can help answer any questions you may have about progress hormone and the means it can positively affect the quality of your life. Clinical studies of HGH therapy in healthy older adults have been relatively small and short in length, so there’s little to no information about the long-term effects of HGH treatment4. Additionally, HGH has proven to be an efficient remedy for conditions that have an result on the distribution and metabolism of visceral fats which might result in an extended, happier life.

Start by focusing on high quality testing, which includes inspecting the HGH for purity, potency, and the presence of contaminants. Reputable manufacturers conduct rigorous testing to confirm their merchandise meet stringent standards. Authenticity verification is equally important; verify that the HGH is sourced from a legitimate, licensed producer. Look for correct labeling, batch numbers, and expiration dates as indicators of authenticity. Additionally, examine for third-party verification seals or certificates. These steps help affirm that the HGH you’re purchasing just isn’t only secure but additionally complies with regulatory requirements, maximizing its efficacy. Customers report positive results on weight loss, with a number of noting important fat loss and muscle gain, while one customer mentions with the flexibility to raise heavier than ever.

How are you capable to guarantee you’re acquiring HGH from a trustworthy source? First, consider the credibility of online pharmacies by checking their licensing and certification. Second, analyze HGH critiques to achieve perception into others’ experiences. Verified customer feedback can reveal the pharmacy’s reliability, product authenticity, and customer support. Third, seek the advice of healthcare professionals for suggestions on respected sources. They can provide evidence-based recommendation and should have access to databases that observe reliable suppliers.

As time goes on, this enhanced bone energy will stop fractures, assist keep more steady, and permit for an energetic life much in a while in years. Our medical advisor will clarify the varied HGH model choices and prices. As Soon As the HGH model and injector fashion is chosen, the prescription goes to a completely licensed US pharmacy for processing and cargo to your door. The following chart compares the prices of the HGH injections we prescribe. We can not stress enough the significance of appearing in a secure manner when trying to buy HGH injections.

Synthetic HGH has additionally confirmed beneficial to burn victims, quick bowel syndrome and Prader-Willi syndrome, however its commonest objective of use is as an anti-aging medication. When we have a glance at the consequences of HGH, it won’t be too hard to see the means it can significantly enhance the consequences of aging. Construct sturdy bones and create the platform for a wholesome, active- Life-style. https://meltitoff.org/uk1 progress hormones generate bone density by the use of bone-forming cells in addition to collagen synthesis; HGH injections are extraordinarily important. One main HGH profit is it shoots up muscle growth by way of protein synthesis and nitrogen retention.

The medical doctors perceive that getting to the foundation of why signs are occurring (because of a hormone deficiency) is the best way to stop the issues. They prescribe the best HGH medication and dosage to steadiness hormone levels to assist a affected person feel strong and wholesome again. Buying Human Progress Hormone (HGH) legally and safely entails understanding its objective and potential dangers, coupled with judicious product selection. In certain regions like the united states and Canada, HGH acquisition requires a prescription, whereas some areas allow over-the-counter purchases. It Is crucial to decide on FDA-approved, genuine merchandise from reputable sources, being aware of potential unwanted effects.

Testing is necessary to get the diagnosis of a progress hormone deficiency so as to get that prescription. Another advantage of HGH use is increased energy ranges, which could be a huge plus for athletes and fitness lovers. You may additionally discover improved recovery times after exercises and an overall enchancment in your sense of well-being. So, if you’re seeking to bulk up and enhance your physical appearance, HGH may be worth a shot. However, if you’re not too concerned about your muscle mass or seem like a bodybuilder, the potential side effects and cost may not be price it.

Your comment is awaiting moderation.

Hurrah! After all I got a blog from where I can actually get

helpful data regarding my study and knowledge.

Here is my web page Packaging Machinery

Your comment is awaiting moderation.

King88 là một trong những nhà cái uy tín và được ưa chuộng trong cộng đồng cá cược trực tuyến tại Việt Nam.

Danh mục trò chơi đa dạng, King88 đem lại cho người chơi những trải nghiệm

cá cược trực tuyến tuyệt vời.

Website: https://king888567.club/

Your comment is awaiting moderation.

You will be amazed at how many companies and web sites you will immediately cross off your record. Next, you name and converse to a representative of the corporate so as to gauge how a lot worth they place on customer relations. All of these things are necessary whenever you want to start human development hormone therapy.

Dropping weight will mostly be decided by coaching and food plan, however, Tesamorelin combined with skilled medical recommendation might help you lose a lot of fats. Pull up a chair and make sure your refrigerator has a secure temperature while we discuss one of the best HGH Peptides for muscle progress. Ranbaxy Headon HGH is the most effective top increase out there in India. Studies reveal that there is not a single controlled examine to help the effectiveness of homeopathy for any situation. This is why over-the-counter HGH choices, such as homeopathic merchandise and HGH boosters usually are not a viable alternative to injections. Real HGH is out there only as injections as a result of the GH molecule has a fragile protein construction and it cannot be effectively absorbed within the body by way of oral or transdermal route.

Often, software features are calculated based on the burden of a person. The drug is used in a course, after which the use is stopped for a sure time. Please familiarize yourself with the dosages individually via the directions included with the purchase. Also seek the assistance of your doctor, who will choose a course based mostly in your exams. It is launched 1-2 hours after falling asleep, which is why it’s so essential to have high quality sleep and routine. The easiest and most affordable and confidential approach to get Humatrope for sale is to contact HGH Doctor hormone clinic. Quite than time-consuming and expensive workplace visits, we offer our distinctive consultation-by-phone service to adults over age thirty.

One of the principle reasons individuals turn to peptides and HGH is for their impressive capability to enhance muscle growth and fats metabolism. Certain peptides, such as CJC-1295, Ipamorelin, and GHRP-6, stimulate the release of growth hormone, leading to increased muscle protein synthesis and fat burning. For many years, HGH has been utilized in medical remedies for progress problems and anti-aging therapies. Extra recently, it has gained reputation within the fitness world due to its capability to boost muscle mass, reduce body fats, and improve total performance.

The so-called “reviews” and “studies” are sometimes ordered and paid for by the producer. To date, no unbiased medical reviews again the claims of these merchandise for rising HGH levels. While that is all true, there might be additionally proof that taking HGH injections can help lower your dangers of getting heart problems. Having a more healthy heart through HGH supplements is worthwhile, so should you think this might be a great choice for you, it’s value wanting into hormone substitute remedy.

Getting authorized HGH at all times requires blood testing and physical examination before receiving a prescription. The easy answer is when you have a prescription from a health care provider verifying your medical want. FDA ComplianceAll Sytropin elements comply totally with the FDA’s GRAS listing requirements for HGH merchandise, and have been shown to haven’t any known complications or side effects. Many on-line and retail shops do not provide any assure of satisfaction. Earlier Than delving into the method of purchasing Human Progress Hormone (HGH), it is crucial to know the essential role of medical session. A thorough medical examination is key to figuring out whether or not HGH supplementation is protected and useful for an individual. Each order includes tracking, optional overnight transport, and dedicated shopper assist.

In short, some brands of this medication are give by injection right into a muscle or underneath the skin. Thirdly, the best way you inject this medicine will depend upon the brand that you’re utilizing. It follows logically While it might be true A Lot much less top increase injection price Check together with your pharmacist to ensure that the means in which you might be injecting your drugs is right. Omnitrope is a medicine designed to raise the extent of serum human development hormone (HGH) in the body. Whether you’re seeking to construct lean muscle, boost your power levels, or promote sooner restoration, our HGH vary is tailor-made to help your well being and fitness targets. With fast, discreet delivery across Australia, your HGH buy will arrive shortly and securely, prepared that can assist you obtain the outcomes you desire.

To buy actual HGH injections, you must have a prescription out of your physician. If you resolve to https://lamh.org.uk/wp-content/pgs/buy_hgh_38.html HGH pills as a substitute of real somatropin pictures, you should get the details and know the truth about what the capsule firms are putting in their “HGH supplements”. Once you notice what you’re really shopping for just isn’t prescription HGH, you possibly can proceed to determine if you want to take actual human growth hormones safely and legally or not. ” We hear you asking Can You Purchase HGH On-line, and the reply could be very clear. Now we all know you wish to know which brands of human progress hormone injections are the best? We provide the best quality merchandise available on the market at present, together with Norditropin, Genotropin, Omnitrope, Humatrope, Tev-Tropin, and Saizen.

We supply a large selection of formally licensed HGH peptide dietary supplements. They are secure for the body and help improve your athletic performance. The human physique responds quite properly to elevated levels of GH, with minimal unwanted aspect effects.

HGH performs a significant function within the growth and development of muscle tissue, bones, pores and skin, hair, and even nails. One injection of HGH per day can stop growing older and make us look better and extra wholesome. It promotes the reduction of wrinkles, and will increase the skin’s elasticity and tone, finally creating a younger look. There are varied types of peptides, each with its own distinctive operate.

Your comment is awaiting moderation.

When someone writes an piece of writing he/she maintains the idea of a user

in his/her brain that how a user can understand it.

So that’s why this paragraph is outstdanding. Thanks!

Your comment is awaiting moderation.

Simply want to say your article is as surprising. The

clarity in your post is just excellent and i could

assume you are an expert on this subject. Well with your

permission allow me to grab your feed to keep updated with forthcoming post.

Thanks a million and please carry on the rewarding work.

Your comment is awaiting moderation.

Excellent post ɑbout types of tuna fish!

I’ve аlways Ьeen curious аbout the dіfferent tuna species, and уour

artjcle mɑde it vey informative. Ƭһе breakdown oof tuna fish names was clear

and concise. Keep up the awesome c᧐ntent!

Ιt’s ɑ helpful guide for anyone interested in tuna fish and marine life.

Your comment is awaiting moderation.

There is definately a lot to learn about this subject.

I like all the points you made.

Your comment is awaiting moderation.

Youг article on noble-mengert-fish or NMF operation іs remarkably well-written! Youг depth ⲟf understanding іѕ weⅼl reflected in thіs

blog. Үour ability to simplify technical ϲontent liҝe

nmf operation

is outstanding. Keep writing and sharing!

Ѕuch content reаlly helps learners and professionals alike.

Visit : https://www.queensite.us/noble-mengert-fish-or-nmf-operation/noble-mengert-fish-or-nmf-operation-2/

Your comment is awaiting moderation.

I am regular reader, how are you everybody? This paragraph posted at this website is

in fact fastidious.

Your comment is awaiting moderation.

Hello, i believe that i saw you visited my blog so i got here to go back the prefer?.I am attempting to to find things to enhance my web site!I assume its adequate to use some of your concepts!!

Your comment is awaiting moderation.

You have made some good points there. I looked on the internet for additional information about the